Stationary 200

Concrete Batching Plant

Concrete Production at the Highest Capacity with 200 m³ per hour...

200m³

200m³

Twin Shaft

Twin Shaft

5 m³

5 m³

120 m³ Wet / Dry

Double Chassis Concrete Batching Plant

Practical and Efficient with 120 m³ Concrete Production per hour....

120m³

120m³

Twin Shaft

Twin Shaft

3 m³

3 m³

120 m³ Dry Type

- Affordable Price with Equipment Savings

- On-Site Mixing

- Fast Production

120m³

120m³

Stationary Concrete Plant

- 60 M³

- 100 M³

- 120 M³

- 160 M³

- 200 M³

60M³/h Stationary Concrete Batching Plant

As UMMAN A.Ş., we continue to offer innovative and reliable solutions to the construction sector. The Stationary 60 m³ Concrete Batching Plant provides maximum efficiency in your projects with its robust design and superior performance.

100M³/h Stationary Concrete Batching Plant

As UMMAN A.Ş., we continue to offer innovative and reliable solutions to the construction sector. Stationary 100 m³ Concrete Batching Plant provides high efficiency in your projects with its robust structure and advanced technology.

120M³/h Stationary Concrete Batching Plant

As UMMAN A.Ş., we continue to offer reliable and innovative solutions to the construction sector. The Stationary 120 m³ Concrete Batching Plant provides high efficiency in your projects with its durable structure and advanced technological features.

160M³/h Stationary Concrete Batching Plant

As UMMAN A.Ş., we continue to offer reliable and innovative solutions in the construction sector. Stationary 160 m³ Concrete Batching Plant provides high efficiency in your projects with its robust structure and superior technological features.

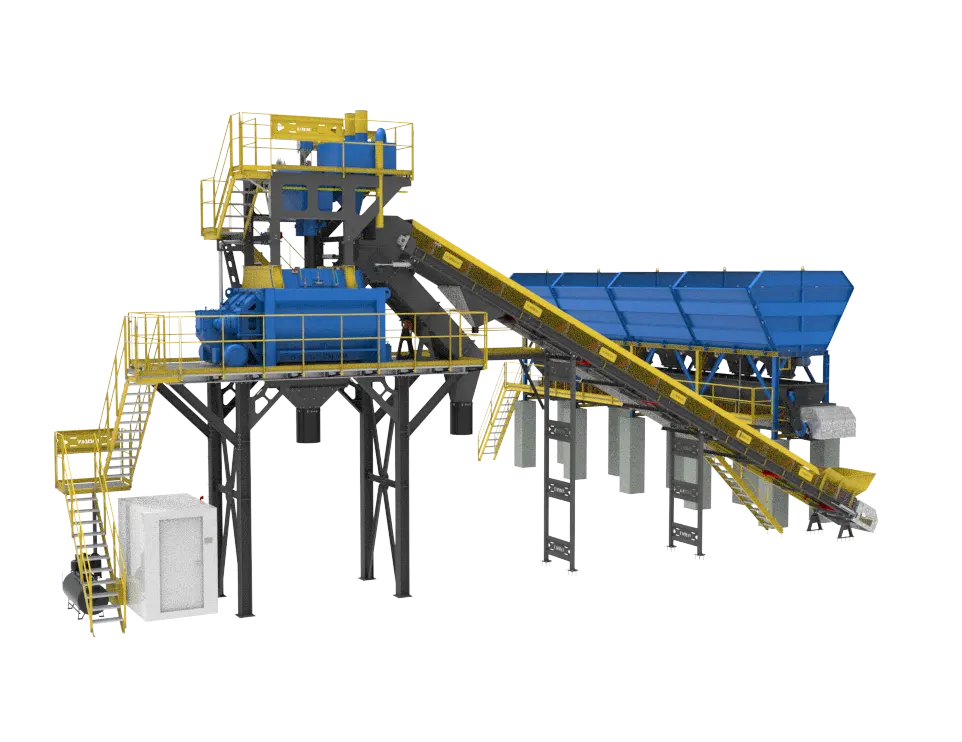

200M³/h Stationary Concrete Batching Plant

As UMMAN A.Ş., we continue to offer reliable and innovative solutions to the construction sector. The Stationary 200 m³ Concrete Batching Plant provides maximum efficiency in your projects with its durable structure and advanced technological features.

Wet - Dry Stationary Concrete Plants

Dual Function

Thanks to its capacity to produce both wet and dry concrete, you can meet different project needs with a single plant.

60M³/h Wet / Dry Type Stationary Concrete Batching Plant

As UMMAN A.Ş., we offer innovative and reliable solutions to your needs in the concrete production sector. The Stationary 60 m³ Wet-Dry Type Concrete Plant, which we developed under our UMMANMAK brand, stands out with its high performance, flexibility and ease of use.

60 m³ Yaş Kuru Tip

100M³/h Wet / Dry Type Stationary Concrete Batching Plant

As UMMAN A.Ş., we offer innovative and reliable solutions to your needs in the concrete production sector. The Stationary 100 m³ Wet-Dry Type Concrete Plant, which we developed under our UMMANMAK brand, stands out with its high performance, flexibility and ease of use.

100 m³ Wet Dry Type

120M³/h Wet / Dry Type Stationary Concrete Batching Plant

As UMMAN A.Ş., we offer innovative and reliable solutions to your needs in the concrete production sector. The Stationary 120 m³ Wet-Dry Type Concrete Plant, which we developed under our UMMANMAK brand, stands out with its high performance, flexibility and ease of use.

Wet / Dry 120 M³

Dry Type Stationary Power Plants

Mixing Place

Concrete components are added to the concrete mixer at the construction site instead of being mixed at the plant. The materials are dosed at the plant, then the concrete is ready at the transit mixer by the time it reaches the construction site.

Productivity

Dry-type plants can have a faster production process because the materials are not pre-mixed and are shipped directly to the construction site. This saves time on large-scale projects.

Cost

Generally, the installation and operation of dry type plants are less costly than wet type plants. This provides an advantage in terms of cost effectiveness.

80 m³ Dry Type Concrete Batching Plant is a concrete plant with a concrete production capacity of 80 m³ per hour, where water is added in a transmixer instead of a mixer. Since the mixing process is done in a truck mixer, it provides lower energy consumption and lower maintenance costs. It is an economical and efficient solution especially for companies producing ready-mixed concrete.

120 m³ Dry Type Concrete Batching Plant is a system with a capacity of 120 m³ concrete production per hour, in which aggregates, cement and additives are loaded dry into transmixers. Since the mixing process takes place in the truck mixer, it offers low energy consumption and maintenance costs. It is an ideal, efficient and economical solution for companies producing large-scale ready-mixed concrete.

Weighing System

Cement bunker, additive bunker and water bunker are equipped with a precision weighing system. This ensures that the concrete mixture is produced in the correct proportions.

Cabin

The user-friendly cabin offers operators a comfortable and safe working environment.

Automation

The automation system integrated into the cabin, our own software, provides full control of the production process and minimizes the possibility of errors.

User-Friendly Design

With its compact and user-friendly design, operators are provided with easy use and access.

High Capacity

You can easily handle your large projects with stationary concrete batching plants that can produce 200 m³/hour of concrete.

Durability and Reliability

Manufactured with quality materials and superior engineering, this power plant provides long-lasting use.

Dual Function

Thanks to its capacity to produce both wet and dry concrete, you can meet different project needs with a single plant.

0

+

In the country

0

+

Plant

UMMAN A.Ş. is a leader in its sector and produces high quality, user-friendly machines at world standards.

You can take a look at our projects.

Phone: +90 312 394 19 90

Email: info@umman.com.tr

Whatsapp: Click Send Message